Tool Management System

1. Easy operation with image comparison

(Comparison of tool photos with actual tools to reduce the occurrence of taking the wrong tool)

2. Intelligent reminders and easy management

(When a problem occurs, LINE NOTIFY will send an alarm to notify relevant personnel to handle it)

3. Cloud-based back-end for convenient queries

(The back-end can query information such as the recipient and quantity, facilitating safe inventory management)

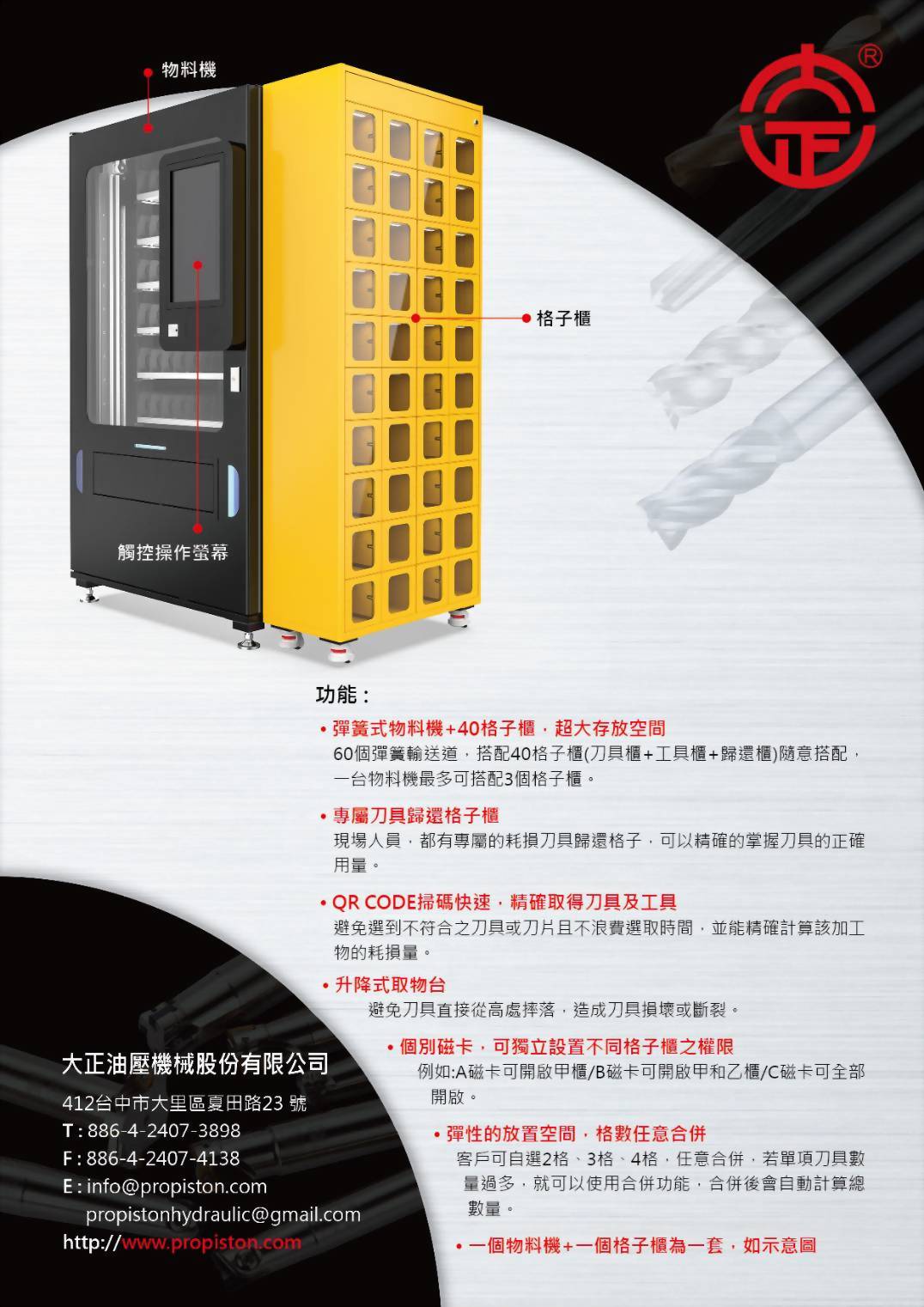

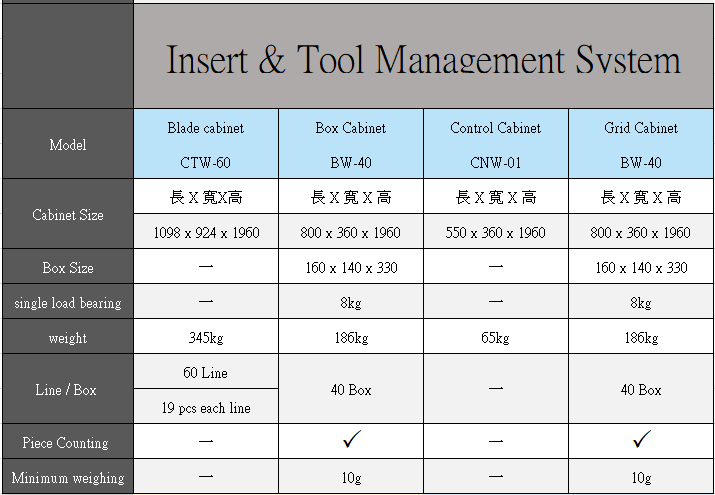

Spring-loaded material feeder + 40-boxes , providing ample storage space.

60 spring-loaded conveyors, paired with 40 boxes

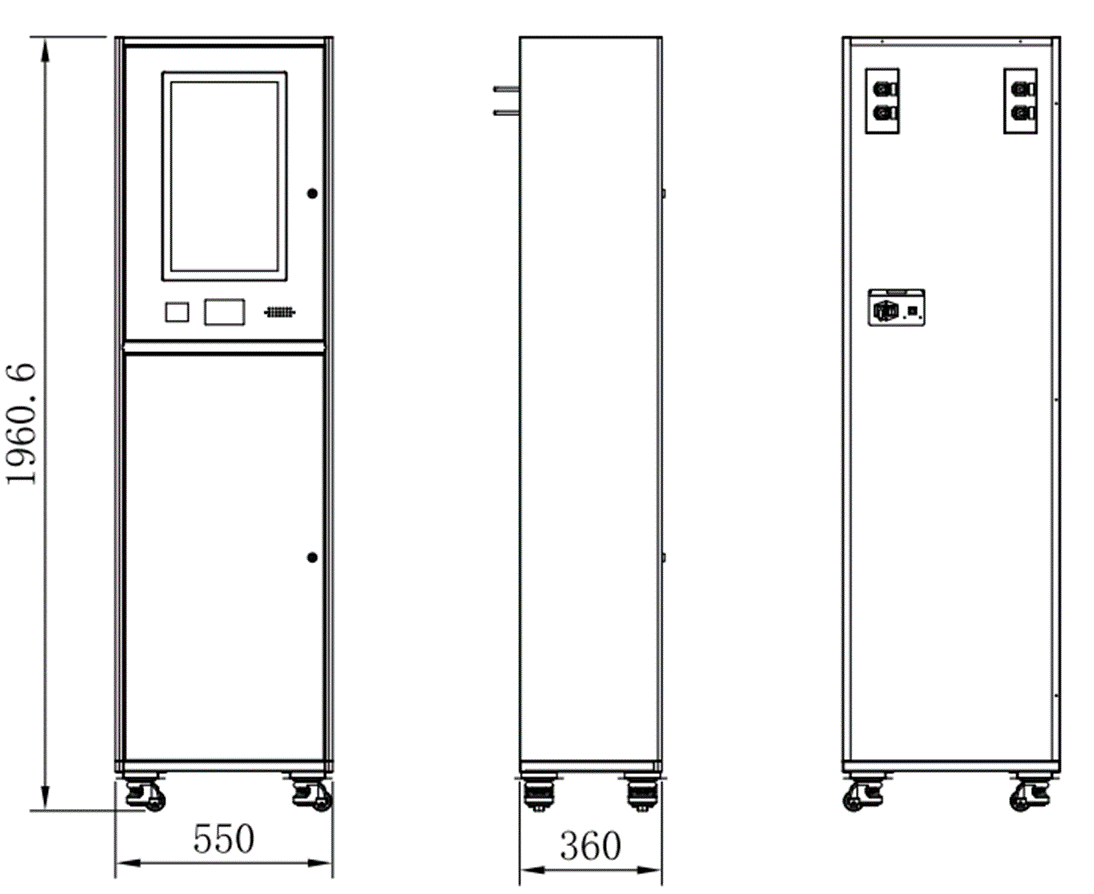

1. (tool cabinet + Cutting Inserts cabinet + return cabinet), freely customizable, with connect up to 15 grid cabinets in series.

2. Exclusive blade return cabinet.

Each on-site staff member has an exclusive blade return cabinet to precisely track the correct usage of each blade..

3.Quick and accurate tool selection with QR code scanning.

Avoid selecting the wrong blade and wasting unnecessary selection time, while accurately calculating the blade usage for the processed material.

4. Lift-type pick-up platform.

Prevents tools from falling directly from a high place,

causing tool damage or breakage.

5. Individual magnetic cards that can independently set cabinet permissions.

For example:

Card A can open cabinet A

Card B can open cabinets A and B

Card C can open all cabinets

6. Flexible placement space, with any number of grids combinable.

Customers can choose to combine 2, 3, or 4 grids as needed.

If there are too many individual tools, the merge function can be used.

The total number will be automatically calculated after merging.

(Comparison of tool photos with actual tools to reduce the occurrence of taking the wrong tool)

2. Intelligent reminders and easy management

(When a problem occurs, LINE NOTIFY will send an alarm to notify relevant personnel to handle it)

3. Cloud-based back-end for convenient queries

(The back-end can query information such as the recipient and quantity, facilitating safe inventory management)

Spring-loaded material feeder + 40-boxes , providing ample storage space.

60 spring-loaded conveyors, paired with 40 boxes

1. (tool cabinet + Cutting Inserts cabinet + return cabinet), freely customizable, with connect up to 15 grid cabinets in series.

2. Exclusive blade return cabinet.

Each on-site staff member has an exclusive blade return cabinet to precisely track the correct usage of each blade..

3.Quick and accurate tool selection with QR code scanning.

Avoid selecting the wrong blade and wasting unnecessary selection time, while accurately calculating the blade usage for the processed material.

4. Lift-type pick-up platform.

Prevents tools from falling directly from a high place,

causing tool damage or breakage.

5. Individual magnetic cards that can independently set cabinet permissions.

For example:

Card A can open cabinet A

Card B can open cabinets A and B

Card C can open all cabinets

6. Flexible placement space, with any number of grids combinable.

Customers can choose to combine 2, 3, or 4 grids as needed.

If there are too many individual tools, the merge function can be used.

The total number will be automatically calculated after merging.

Login

Login